Digitalisation in the industrial machinery sector-October 2019

Manufacturing in the UK is thriving. The sector, which contributes more than 10 per cent of the UK’s GVA, accounts for nearly half of the country’s exports and employs 2.7 million people.

However, since 2009, productivity growth in the UK has been trivial – perhaps 1 per cent per year. In contrast, industrial rivals such as Germany, Spain and Italy have seen productivity, and consequently national wealth, grow strongly. There seems to be little consensus about why this has happened. But increasingly, there is agreement on the solution: digitalisation, including automation, machine learning and Big Data analytics.

In September 2019 a dozen senior digitisation, innovation and IT professionals met at the Goring Hotel in central London to discuss this crucial issue. At this meeting, sponsored by industrial automation specialists Siemens, several major sectors of the UK industrial economy were represented, including packaging, printing, aerospace, industrial machinery and construction, ensuring a practical and wide-ranging discussion.

For more information visit www.siemens.com

Digitalisation strategy

The discussion started with a consideration of digital maturity and how to measure it. KPIs from digitalisation, it was pointed out, may not all be directly relevant to the bottom line. Closer customer relationships, greater perceived value, more engaged employees – these are all part of the value that digitalisation brings. And where the ROI is financial, the return may only be seen in the mid-term rather than immediately. So what are the goals of digitalisation? Increased revenues, of course, as a result of those closer customer relationships. Better quality delivered by highly engaged workers. Decreased costs, too. But perhaps more important is the confidence that digital technology can bring. Better and more data collected during digitised processes means that the fidelity of planning models can be increased, reducing risk and increasing the opportunities to innovate.

Innovation and digital opportunities

Digital technology can drive innovation. For example, it allows the “virtualisation” of factory machinery. At the meeting, Brian Holliday from Siemens explained how they ordered a Cartesian picker (or gantry robot). Before delivery they demanded the machine’s CAD data and animated it, building a digital twin with which they could run different scenarios. This enabled them to effectively debug the picker before delivery, a process that saved hundreds of thousands of pounds, as well as generating huge innovation around the way the picker could be used. Running different virtual scenarios enabled most risks to be taken away or mitigated. A very strong use-case for digital technology is that it allows predictive maintenance. With the right sensors collecting the right data, machinery can be monitored for events that can indicate potential problems and taken out of service before problems occur. Where predictive maintenance is offered as a service to a client, there is a need for trust on the client’s part. This is sometimes generated after a couple of expensive incidents where maintenance was delayed. Data gives you stability and a better understanding of how circumstances are changing. It allows you to innovate because it reduces risk and helps you understand any remaining risk. Data-supported (as opposed to data-driven) decision making is a strong driver of innovation, quality and cost reduction.

Overcoming obstacles

Digitalisation isn’t always simply to achieve, though. Delegates described a number of obstacles. The environment surrounding capital allowances in the UK is unhelpful. And all too often accountants and shareholders make demands for short-term ROI which cannot be delivered (unfortunately short-term ROI is often achieved at the expense of mid-term stability and long-term growth). In addition, engineers sometimes focus on what can’t be done rather than looking for the opportunities digital technology can deliver. And while it is natural for engineers to have a risk-averse mindset, a lack of imagination can hinder the opportunities for digitalisation. What is needed is confidence (driven by data), aligned with the knowledge that specialist employees, or contracted specialists, can bring. Leadership, delegates agreed, is also essential. Digitalisation starts from the top, driven by leaders with ambitious vision who understand that transformation through technology is something that runs across the whole of an organisation, including third parties and the supply chain. These leaders realise that digitalisation isn’t just tactical, it is a strategic imperative that will be driven internally by strongly commercial people who are confident with technology. They accept that success is dependent on people and culture rather than just technology. And they realise that one of the strongest enablers is the building of an ecosystem of expertise with suppliers, academics and even competitors brought into the loop.

The importance of domain knowledge

Detailed domain knowledge is needed to manage technology. In the past this has been considered to be a source of competitive advantage among industrial machinery manufacturers. However, this is less true today. As workers move between employers more frequently, they take domain knowledge with them. The solution here may be formal knowledge-management processes to preserve knowledge within an organisation. In addition it may be necessary to pay experienced tradespeople more to encourage them to stay. Or, counter-intuitively, the solution may be to accept that unique domain knowledge is no longer so important. Start-ups often share domain knowledge freely, while rapid technological change means that it dates rapidly. Perhaps the real solution, one delegate suggested, is to rely on hiring expertise when it is needed.

Company culture drives successful digitalisation

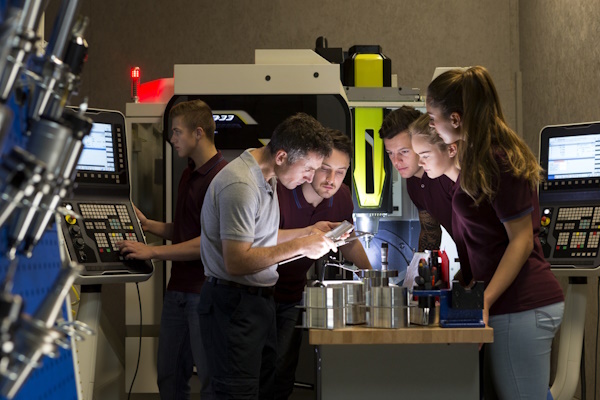

The discussion moved on to a wider consideration of organisational culture. What are the elements of a culture that supports digitalisation? Having the right people is important. People need to be skilled across several disciplines (because technology crosses disciplines) and have excellent problem-solving skills. They need the right training with both “hard” technological and “soft” people-related skills being offered. And in a time of constant change, continuous, life-long learning is essential if your workforce is to be kept abreast of emerging technological opportunities. Diversity is also important if organisations are to benefit from different points of view, experiences and ways of thinking. Unfortunately the UK seems worse at promoting diversity than many European competitors. And diversity at board level is just as important as diversity on the shop floor. If it doesn’t exist then organisations should use non-executive directors to add diversity and additional digital experience. “Track the FUD (fear, uncertainty and doubt) and the VUCA (volatility, uncertainty, complexity and ambiguity)” one delegate suggested. Identifying what people are frightened of and reassuring them is important. VUCA may be more difficult to handle. Volatility and uncertainty are here to stay but again, reassuring people that the organisation is prepared for change and has contingency plans in place will go a long way to maintaining a confident workforce. Incentives are also important when it comes to building a culture that is open to digitalisation. For example, people are often rewarded for cutting costs. But the way this is done is important and some organisations will reward people based on how they worked as well as what they achieved. In this situation an executive who saves costs by bullying would not be rewarded. Similarly, one who saved short-term costs by building up long-term problems would not benefit. So if digital opportunities were discarded because they involved short term gains at the expense of medium-term growth or long-term stability this would not be regarded as commendable. Changing the culture of an organisation to one that supports digitalisation is not easy. There has to be a focus on changing the way people think and act while maintaining the organisation’s core values. And attention needs to be paid to sceptical individuals, in whatever role, who are discouraging about the potential of digital technology. Again, data can help to prove the case.

At the end of the day, it’s all about data

Organisations that hope to transform themselves digitally need to start by focusing on data. They must consider how data about the past can be combined with experience and common sense and used to make relevant, confident and low-risk predictions about the future. When doing this there will always be a need to avoid “data swamps”. Organisations have the potential to generate unmanageable amounts of data, not all of which is useful. Prioritising the data that gets used and the insights that are produced is essential. Businesses have always run on data. But now the platforms that collect and analyse it are more powerful, and the assets they produce are even more valuable. By accepting that data is at the heart of any organisation, transformation into a truly digitalised organisation becomes possible.For more information visit www.siemens.com

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2024, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543

We use cookies so we can provide you with the best online experience. By continuing to browse this site you are agreeing to our use of cookies. Click on the banner to find out more.