Energy efficiency is still an under-exploited opportunity

Sponsored by ABBA new playbook highlights actions industry can take right now to reduce energy costs and carbon emissions

The world’s energy systems are facing an unprecedented set of challenges. Security of supply is no longer assured, while soaring costs threaten the health and safety of consumers and are a brake on industrial growth. At the same time, we must address climate change by driving down carbon emissions to achieve our Net Zero goals.

While the transition to renewables is of course vital to decarbonisation, there is a question that is still largely overlooked – why aren’t we trying much harder to make better use of the energy we already have? In industry, far too much energy is wasted needlessly by aging and inefficient equipment. It is a real problem since, according to the International Energy Agency (IEA), industry consumes around 42 per cent of the world’s electricity, equal to more than 34 exajoules of energy.

There is simple and effective technology available today that can transform industrial energy efficiency. The challenge is that this massive opportunity is still underexploited. That is why ABB has worked with the Energy Efficiency Movement to create a report showing how improving industrial energy efficiency is the fastest and most effective way for a business to cut energy costs and greenhouse gas emissions. The Energy Efficiency Movement is a global forum of around 300 organisations sharing ideas, best practices and commitments to create a more energy-efficient world.

The Industrial Energy Efficiency Playbook includes 10 actions that a business can take to improve its energy efficiency, reduce energy costs and lower emissions right now. It focuses on mature, widely available technology solutions that will deliver rapid results and return on investment (ROI) and which are capable of being deployed at scale.

Recommendations range from carrying out energy audits to right-sizing industrial machines that are often too big for the job at hand, which wastes energy. Speeding up the transition from fossil fuels, by electrifying industrial fleets, switching gas boilers to heat pumps or using well-maintained heat exchangers will also offer efficiencies.

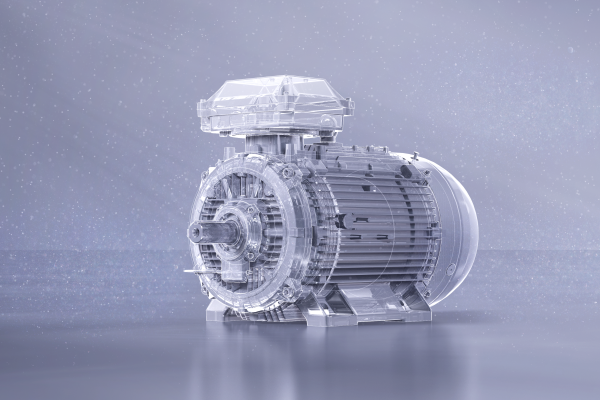

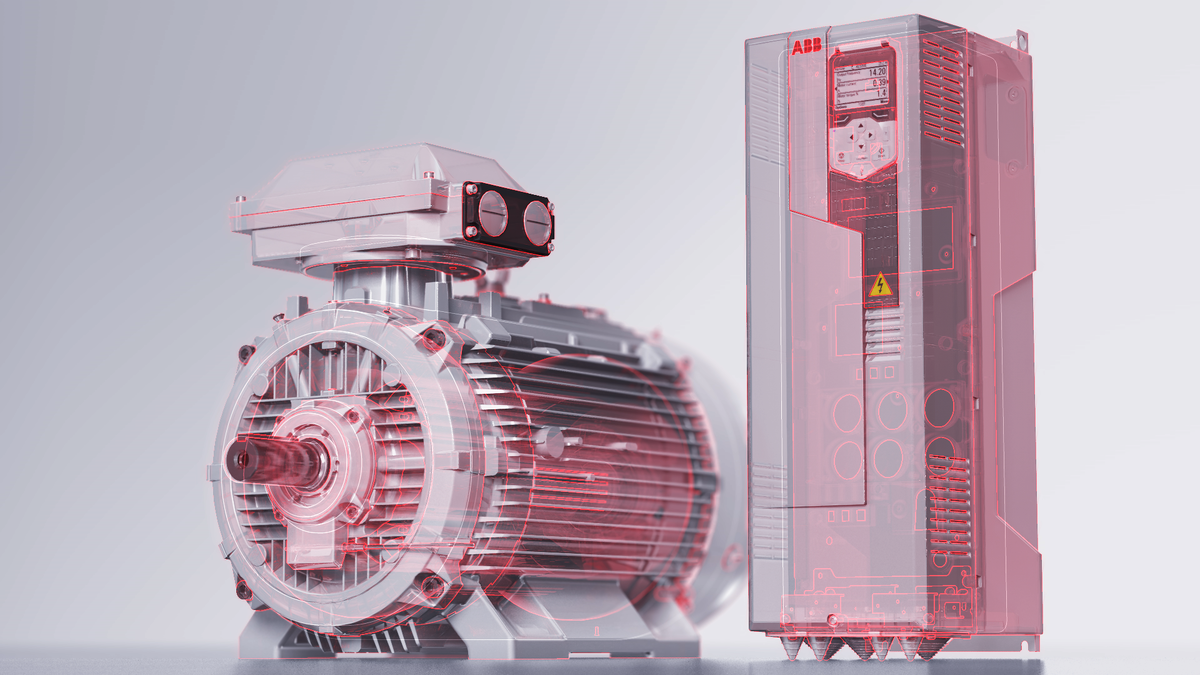

A key focus is on the powertrains used in countless industrial applications to convert electrical energy into motion. The main elements of an industrial electric powertrain are the motor, variable speed drive (VSD) and the application itself, such as a pump, fan or compressor. It is estimated that an astonishing 46 per cent of the world’s electricity is used to produce mechanical energy through electric motor-driven systems. In industry, the consumption rises to two-thirds of total electricity.

The International Electrotechnical Commission (IEC) establishes a range of international efficiency (IE) standards for motors, ranging from IE1 (“standard”) to IE4 (“super-premium”). There are moves to introduce an even more advanced standard, IE5, already reached by synchronous reluctance (SynRM) motors.

VSDs control the speed of motors and the amount of torque produced so that the energy consumed is intelligently calibrated to match the amount of work that needs to be done. Installing variable-speed drives can improve the energy efficiency of a motor-driven system by up to 30 per cent to deliver immediate cost and emissions benefits.

Upgrading to a more efficient motor technology now will yield significant efficiency gains that result in major energy and emissions reductions. With energy prices at an all-time high, these measures can pay for themselves in less than a year.

Furthermore, it has been estimated that if the more than 300 million industrial electric motor-driven systems currently in operation were replaced with optimised, high-efficiency equipment, global electricity consumption could be reduced by up to 10 per cent.

Hand in hand with the need to increase energy efficiency is the pressing need to establish an effective circular economy.

Investment costs in new equipment such as motors can be recouped, but businesses are concerned about the impact this will have on their carbon footprints. There is also the issue that some of the materials used, particularly copper, can be carbon heavy.

That is why we are purchasing low-carbon and recycled copper from Boliden, the Swedish mining and smelting company, for ABB’s high-efficiency electric motors produced in Europe. The two companies have also signed a memorandum of understanding that will see ABB supporting Boliden in identifying inefficient low-voltage motors across its operating units. These motors will be replaced with high-efficiency motors, while the old motors are recycled to provide raw material for Boliden’s recycled copper. This creates a tangible “virtuous circle”.

While we support our customers and suppliers in reducing their CO2 emissions, an essential part of accelerating the green transition involves turning this focus inwards as well. That is why we have already switched our motors and generators manufacturing unit in Vaasa, Finland over to green electricity, with plans for expansion in additional locations.

The technologies essential for greater industrial energy efficiency are available and ready to go right now. As well as reducing carbon emissions they make perfect commercial sense since they will help cut energy bills. That is why the energy efficiency of electric motors must shift from an underexploited opportunity to the top of the business agenda.

You can read ABB’s industrial energy efficiency playbook here: global.abb/topic/ee-playbook/en

By Stefan Floeck, Division President IEC Low Voltage Motors, ABB Motion

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543