Why global supply chain solutions are digital

Sponsored by InspectorioRebuilding resilient supply chains requires a new level of transparency and collaboration

If there’s one lesson we’ve learned from the COVID-19 pandemic, it’s that modern, interconnected supply chains are inherently fragile.

While interconnection accounts for some of a supply chain’s strengths — nimbleness, product diversity, a tighter bottom line — it also requires tracking software to manage a global supply chain in real-time, which makes digital transformation an absolute necessity for brands and retailers.

In a 2020 survey from McKinsey & Co, 93 per cent of senior supply chain executives reported an intent to make their supply chains “far more flexible, agile and resilient”. A year later, that success was found to be “strongly linked to [the] use of modern digital tools, especially advanced analytics.”

As supply chain complexity and risk evolve, so too must our supply chain management capabilities. Conventional approaches, including vendor consolidation and just-in-time capacity, no longer cut it. As PwC writes, companies “need to rebuild for the future … businesses [need] to prioritise supply chain transformation for resilient growth.”

What’s the solution?

However, a digitised supply chain doesn’t simply brace you for disruptions: it saves resources, controls stock levels and helps you rapidly adapt to changes in demand. Risk will continuously haunt your operations, and your ability to thrive despite risk depends on how willing you are to reimagine your supply chain.

The drivers of supply chain transformation, such as "sustainability" and "resilience" (and other industry buzzwords) are essentially about being prepared for risk. An efficient supply chain network is one that can absorb disruption and weather uncertainty – in other words, one that can detect and quantify different categories of risk.

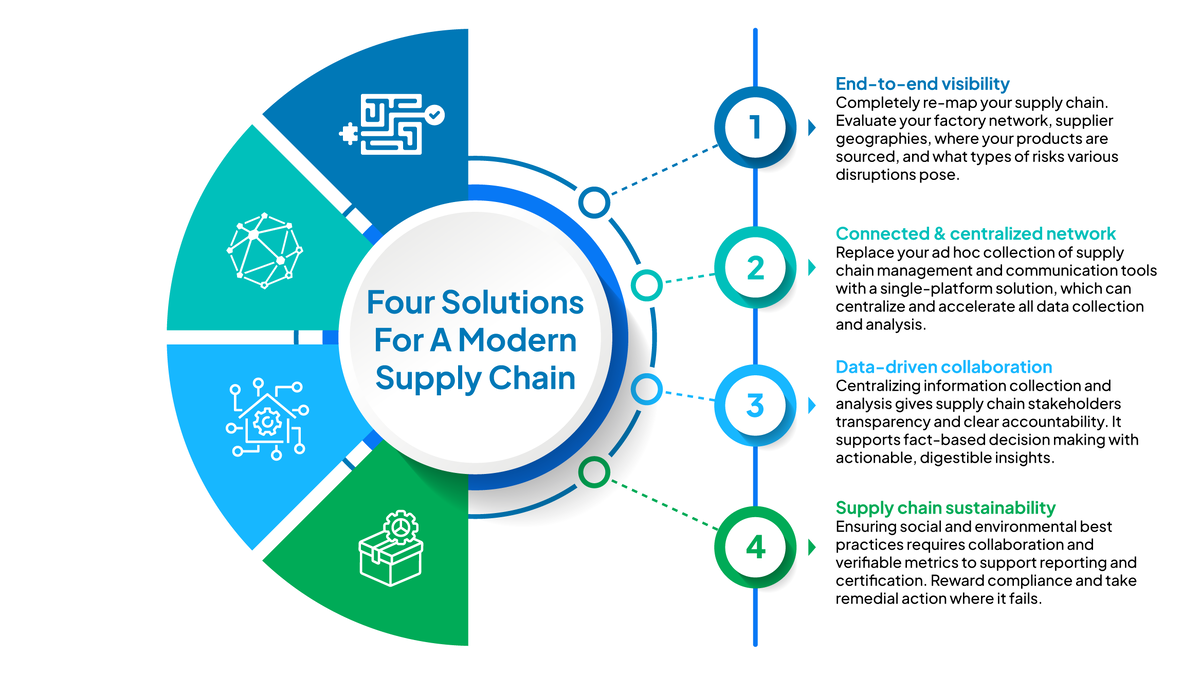

Below, we’ve summarised four solutions to achieve an efficient, modern supply chain, trackable in real-time. Compare it to your own supply chain to gauge its efficiency and sustainability.

1. End-to-end visibility

The first step to a supply chain reset is to completely re-map it. Evaluate your factory network, supplier geographies, where your products are sourced and what types of risks various disruptions pose.

Next, make sure you can track and monitor production in real-time from origin to shipping and quickly report on desired metrics.

Announcing Inspectorio’s US$50 million series B funding in early 2022, Carlos Moncayo, Inspectorio’s CEO and Co-Founder, said that “Inspectorio is invested in creating end-to-end visibility and insights into the production chain and improving traceability through a one-of-a-kind holistic view into quality, sustainability and production tracking.” That degree of visibility is only possible with the right level of technology.

2. A connected and centralised network

Without the right tracking software to centralise production management, upending conventional supply chain practices is an unenviable task. Part of the reason is the tendency to deal with complex supply chains by introducing multiple ad hoc systems to manage them, which then leads to silos.

A single-platform solution empowers you to organise fragmented supply chains at scale by centralising all data collection, monitoring and communication. Automated processes speed up reaction time, reduce resource burden and decrease clutter by assigning clear accountability.

When all stakeholders rely on the same dynamic platform as their source of validated data, decision-making becomes fact-based and efficient.

3. Data-driven collaborations with partners

Information collection is essential to data-driven collaboration, but it is only the first step. The second, equally important, step is to be able to make sense of it.

“The ability to gather this data and to analyse or organise it in a way that makes sense to you is key,” said Art Isaacs, Chief Compliance Officer for InMocean Group in a recent webinar. Armed with actionable, digestible insights, you can catch potential issues early on, standardise workflows across your network, identify the root causes of problems and engage with supply chain partners effectively.

4. Supply chain sustainability

Ensuring social and environmental best practices across your supply chain will require transparency over your shared operations, which means collaboration and trust.

Harvard Business Review suggests that companies “should also work directly with their suppliers’ procurement units on the best ways to disseminate sustainability requirements throughout their supply networks”. With a production tracking platform, you can share up-to-date standards with every partner in your supply chain and monitor their compliance in real-time. This high-resolution oversight allows you to reward good behaviour with more business or autonomy and to take remedial action where compliance is threatening to fail.

The quality and reliability of your suppliers will have a tremendous impact on the resilience of your business. Failing to ensure sustainability through product compliance can prove fatal to your supply chain.

As you work towards a more efficient supply chain, you should ensure your production tracking platform matches your needs. Learn more in Inspectorio’s free eGuide on choosing the right software.

By Fernando Moncayo Castillo, Managing Director and Co-Founder, Inspectorio

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543