Closed-loop packaging solutions that aim for a more sustainable future

Sponsored by Corplex

Lucas Van der Schalk, CEO, Corplex

3R principle : reduce, reuse, recycle

They are currently at a low point in public opinion. But, says Corplex CEO Lucas van der Schalk, plastics – depending on how they are produced and used – can be both useful and beneficial to environmental conservation.

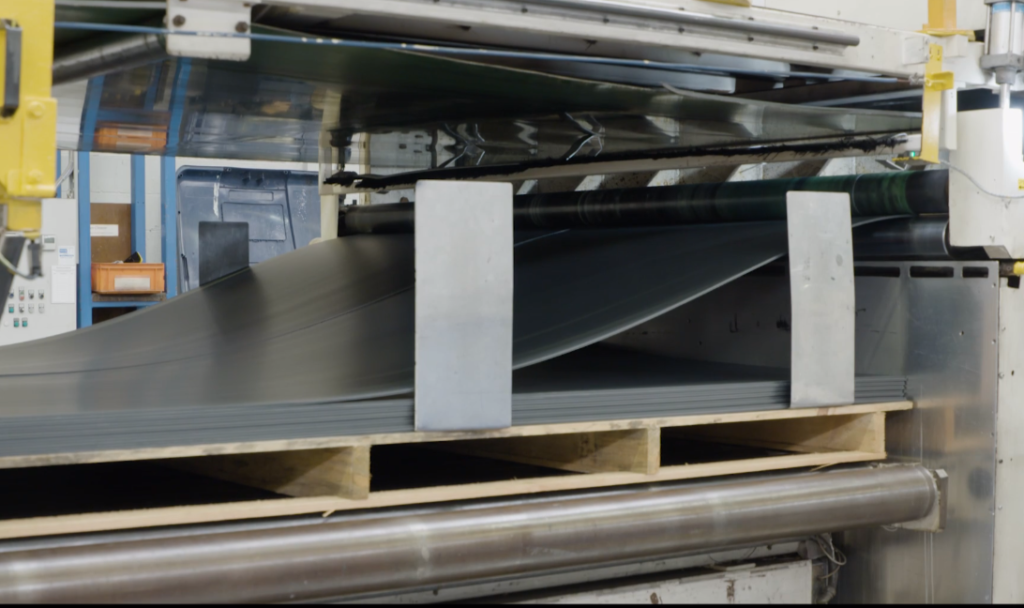

Sustainability shouldn’t be an end point, but a way of life. At Corplex, that means reducing the amount of waste that’s being created to begin with – from the material itself to the amount of air that is shipped – and lowering the carbon footprint for both Corplex and its customers. Only once this has happened can new packaging solutions, that enable us to reuse and recycle materials most effectively, be designed and introduced into a new production cycle. “The simplest way of putting it is that very little waste leaves our sites,” says van der Schalk. “All of our sites are self-contained insofar as they produce the products and convert them into whatever is needed – the final product will then be ready for the customer.”

Changing the concept of recyclability

Corplex doesn’t just recycle its own industrial waste, it also works with customers to help take some of their waste back. “We work with a third-party supplier to take this post-industrial material and turn it into pellets that can also be introduced into our production cycle,” says Lucas. “At Corplex, plastic is a resource that can be recycled many times.”

Closed-loop systems: the key success factor to boost sustainability by reducing carbon footprints

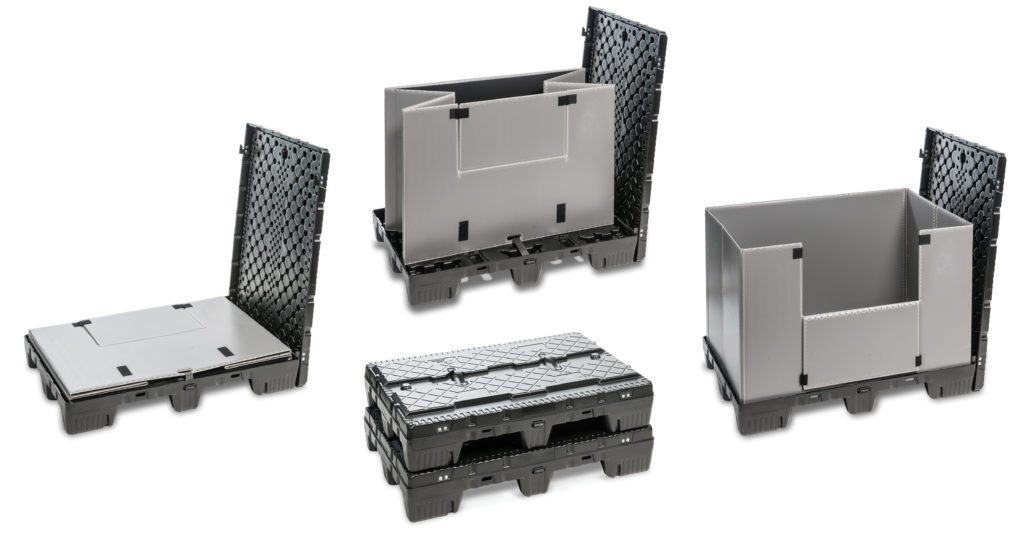

Corplex aims to “close the loop” in the recycling process, reducing waste and material loss, and using fewer raw materials. And with packaging not only customised to the size of your goods, but also optimised to the dimensions of the trucks carrying it – and entirely foldable when empty – your logistics flow can be simplified and your carbon footprint drastically reduced.

“This means that only one in four trucks have to return to the supplier. On average we save around 300 tonnes of CO2 per product per year. Think how many thousands of products go into the car – it’s hundreds of thousands of tonnes of CO2 being saved.”

For more information on Corplex Circular Plastics Solutions, click here.

Listen to the podcast here.

Business Reporter Team

Related Articles

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543