How AI is driving the future of manufacturing, one tool at a time

Sponsored by AutodeskAutodesk’s Jeff Kinder on why digital transformation is a win-win for consumers and businesses

Over the past few decades, society has lived through ongoing stages of technological transformation. Music went from records to cassette tapes to CDs and now streaming platforms such as Spotify. Television was born with black-and-white TV sets and antennas, evolving through cable and satellite television to today’s on-demand, anywhere, anytime streaming services. Just 15 years ago, banking at home via an app was in its infancy. Now, that’s the norm.

This thread of streamlining daily processes has naturally found its way into the workplace. Communication tools such as email and Slack have revolutionised how we communicate at work. Cloud-based services such as Dropbox and Google Drive enable teams to store large quantities of data and share files easily. Some design and manufacturing businesses are using AI-powered tools such as generative design to create design options faster than ever before – and there is still room for growth.

Jeff Kinder, executive vice president of Product Development and Manufacturing Solutions at Autodesk, has played a key role in supporting various industries as they underwent digital transformation – from travel to banking and now design and manufacturing. Here, he shares his insights on the tools powering design and manufacturing’s current digital transformation.

In general, what effects does digital transformation have on businesses and consumers?

Digital transformation puts new tools, and a new level of efficiency, in peoples’ hands, opening up their opportunity to streamline processes and innovate. This ultimately benefits consumers through cost savings, improved product quality and enhanced customer experiences.

Building on that, how is the digital transformation in design and manufacturing impacting the industry?

Leaders in the design and manufacturing industry are currently focused on creating the ultimate connected factory. This vision encompasses seamless communication and collaboration between people and machines, driven by access to real-time data and advanced analytics. The benefits businesses in this space can expect to reap from undergoing transformation include enhanced efficiency, waste reduction and a productivity boost.

As companies adopt more efficient production processes, they can significantly lower production costs. These savings often translate to reduced prices for consumers, making products more affordable without compromising quality. Improved efficiency and innovation in manufacturing can also yield higher-quality products and faster time to market. This ensures that consumers have access to the latest and best offerings more quickly, and the manufacturers bringing these products to market have a jump on their competitors. Plus, it means many more options to choose from on the market.

What are some common challenges manufacturing businesses face today that digital transformation would help solve?

Many companies still use paper and whiteboards to track their manufacturing processes and design changes. They’re fully aware that it’s inefficient, and they want to collaborate faster with colleagues and suppliers who are at a distance from the shop floor. However, their data management system is often local and not in the cloud, which holds them back. Paper travellers – literal envelopes of paper checklists and job instructions – are still much more common than you’d expect. Autodesk’s role is to meet design and manufacturing businesses where they are and help them take next steps toward using the digital tools available today that help them make better decisions faster.

What tools are powering design and manufacturing’s current digital transformation?

To some it may sound cliched, but in numerous regards, the cloud is absolutely transforming the manufacturing industry. Anyone anywhere can work on the same project at the same time – whether it’s a team of designers working remotely or communicating with a manufacturer on another continent.

The cloud is completely shifting how companies use data, approach workflows and systems and spur new growth. It’s all about connecting people, processes and the entire manufacturing ecosystem. And there’s the tangible result of designing and making products with lower cost and less waste.

Automation, which increasingly goes hand-in-hand with the cloud, is another big trend shaping this current wave of transformation. The design and manufacturing industry has embraced automation since the industrial revolution and the early assembly line. It’s really a cornerstone throughout the industry’s history. The current wave of automation sweeping the industry is all about leveraging robotics and AI-powered tools.

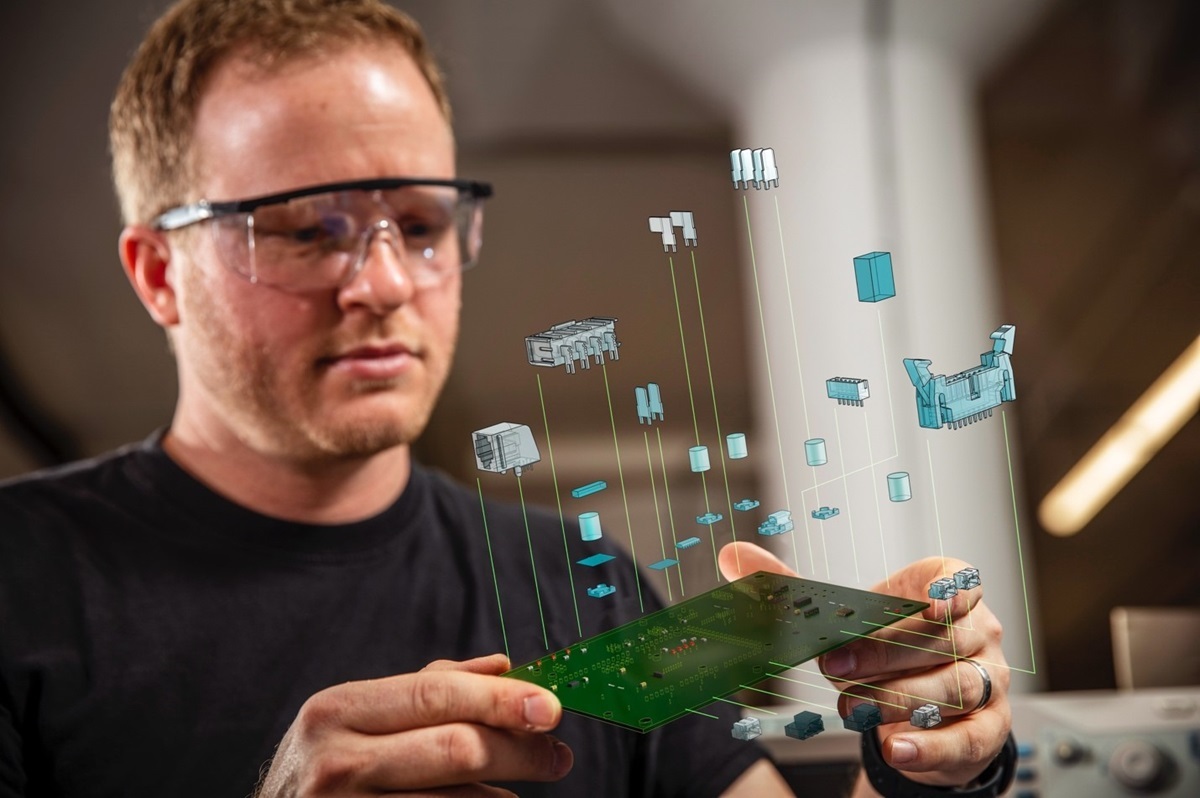

For example, as more and more businesses realise the benefits of achieving optimised designs faster, we’re seeing a wave of adopting automated design tools such as generative design. Within minutes, generative design enables you to prioritise things such as weight, materials, strength and more to analyse and arrive at ideal design ideas, alleviating the pain – and cost – of designing multiple iterations from scratch.

How is the industry reacting to these shifts?

Transformation of any kind is difficult. There will always be resistance at first. However, when you do it right – and with the right partners supporting the process – the reward is massive for both businesses and end-customers.

One of the most difficult stages of getting businesses on board with the cloud is changing the workforce’s mindset around data security. And then actually implementing new tools and procedures brings its own set of logistical challenges. There’s no debating either of those hurdles.

The design and manufacturing industry has not grown up with ease-of-use as a hallmark when it comes to its technology tools and data management. At Autodesk, it’s our job to help companies realise the benefits of moving to the cloud in the context of their specific business needs. For both large and small customers, we focus on guiding companies to a modern, efficient, productivity-increasing design-and-make experience.

Is there any trepidation from businesses?

This might sound surprising, but manufacturers really do like new and emerging technology because it provides an advantage in an increasingly competitive industry. Manufacturers have long embraced technology changes to drive productivity in their industries. As technology change accelerates, manufacturers can’t afford to fall behind, so they continue to learn new tools and adapt.

Once they see the benefits of new tools and procedures, it becomes readily apparent why continually staying on top of what’s around the next corner, technologically, is important. However, they also can’t follow every whim because switching costs are real. At Autodesk, we partner with our customers to help them understand what tools and workflows are really going to make a difference to their businesses.

What is the most exciting way Autodesk is contributing to the manufacturing digital transformation?

Our belief is that if you want to achieve breakthrough productivity gains, you need to bring all design and manufacturing capabilities together into a single, connected digital environment, or “industry cloud”.

Autodesk Fusion is our answer to this, and we’re seeing it replace the “this tool cuts, then this tool drills, then this tool polishes” point-to-point solutions of the past. Customers once had to develop a product design in one tool, then engineer it in another, then program its manufacturing in another. Now, they can do it all with one tool.

With Fusion that step-by-step workflow and all the related data is connected. People don’t have to put a thumb drive in a machine, take it out and stick it into another machine to transfer important project data. Data from the manufacturing process, and even from the shop floor, can cycle back “upstream” to the design process, to improve the process of designing and manufacturing the next product.

What kind of progress have you seen with design and manufacturing companies moving to the cloud?

In today’s industry landscape, some companies are starting to see that if you’re not leveraging the cloud during product development, you’re falling behind. Customers are ready to move to the cloud because the benefits are so tangible. People are coming to understand the cloud is reliable and their data is protected. It’s been exciting to see this shift because it unlocks so much potential for collaboration, lowering cost, and connecting data. Now, as we continue to introduce AI, having your data in the cloud makes it usable for AI models as well.

Speaking of AI, what will be its impact on design and manufacturing?

It’s interesting to see the sudden interest and adoption of AI compared to the adoption of the cloud. The cloud was such a new concept and there weren’t too many consumer or commercial examples that people could initially grasp onto. But now we casually stream music and movies from the cloud, and get our maps and traffic information from it instantly. It’s so engrained in our daily lives that we almost take it for granted. AI, on the other hand, seemed to have sprung from nowhere and now is everywhere.

AI isn’t new to Autodesk, though. We pioneered the introduction of AI and machine learning for manufacturing with generative design more than 10 years ago, and we set up an AI research team shortly after that. So as AI exploded, we were well positioned to launch Autodesk AI last year at Autodesk University. That was just its debut – expect to hear more about Autodesk AI in the months and years to come as we evolve it to help our customers get the most out of what AI can offer.

One recent example of how we’re already delivering on this initiative is the launch of drawing automation in Fusion. Creating 2D drawing versions of 3D models is a vital step in product development because they essentially act as design blueprints for manufacturers to interpret and work from during production. However, we found that engineers spend as much as 40 per cent of their design time creating drawings.

Drawing automation eliminates the tedious steps involved in this process by automatically generating an accurate 2D drawing. It helps engineers design faster, be more productive and communicate more effectively with manufacturers.

As you mentioned, digital transformations are constantly evolving. How should businesses prepare for the next one?

As soon as you believe a digital transformation is over, the clock is already ticking for your next one. You need to think about it as a continuous process. You always need to aim for more digital maturity, and part of that maturity is embracing that there will always be change.

Autodesk’s goal is for our customers to stay ahead of the technology curve at their own pace. We’ll continue to focus on helping them adopt cloud technology, understand the benefits of digital transformation and discover how data management can help them collaborate better. We’re going to make it easy and intuitive with the ability to realise value quickly. That’s a must.

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543