Revolutionising UK manufacturing with AR solutions

Jan Junker at TeamViewer argues that manufacturers can leverage AR advances to revolutionise operations and refine production methodologies

The UK industrial sector is booming and manufacturing, in particular, is one of the most important industries for the UK economy. In fact, Make UK’s most recent annual analysis found that, in 2022, UK manufacturing had a £183 billion output, making it the ninth largest manufacturing nation in the world. Despite this success, the sector is still contending with many challenges.

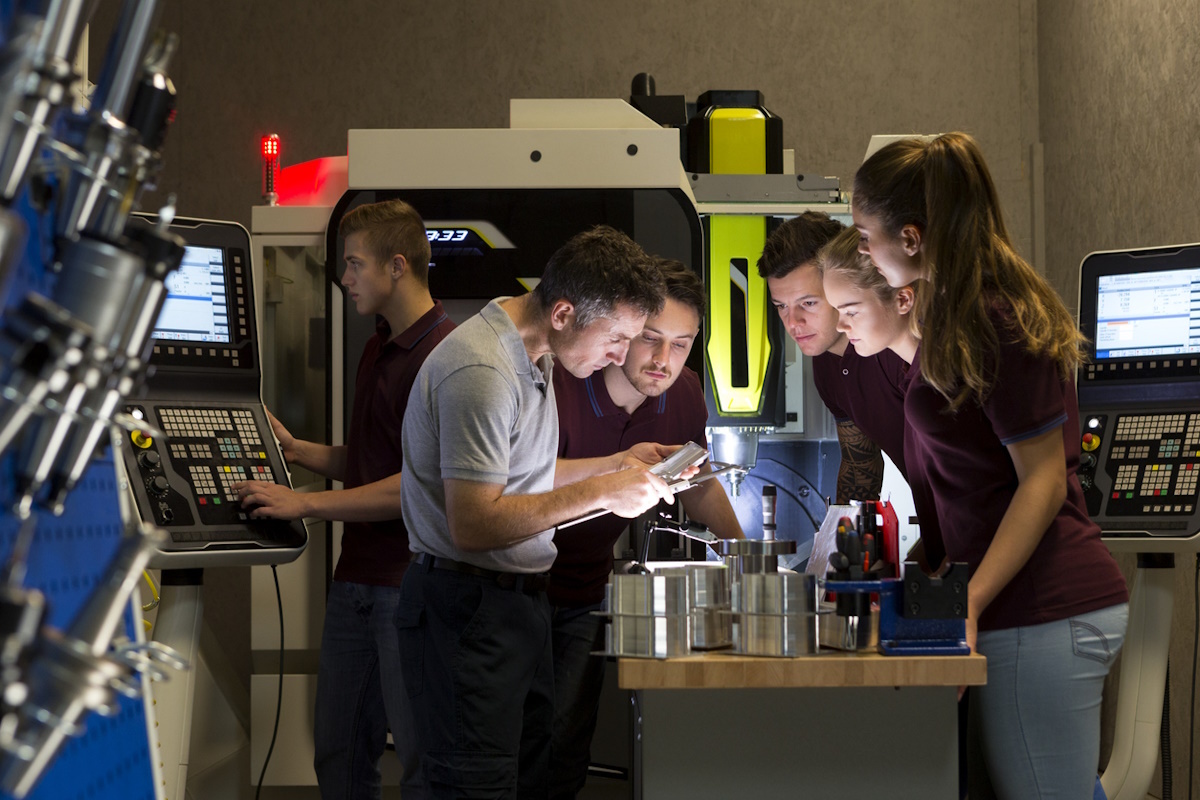

One such issue is an ageing workforce. As seasoned professionals near retirement, it’s becoming increasingly vital that these workers share their invaluable knowledge with the upcoming generations to ensure the industry can continue to thrive.

Simultaneously, there’s a growing need to ensure safer and more streamlined operations for frontline staff. To confront these pressing challenges and unlock further advantages, UK manufacturers should explore the potential of cutting-edge technologies, such as augmented reality (AR).

In recent years, specialised AR technology, tailored to specific industries, has been seamlessly integrated into shopfloors. Manufacturers can leverage these same technological advances to revolutionise operations and garner greater profits, product standards, and refine production methodologies.

Optimising production processes

In the high-risk manufacturing environment, human involvement naturally creates safety risks and errors can, in worst-case scenarios, lead to accidents. Alongside injury, human error can compromise product excellence at a cost to the wider business. By digitising process through AR, these risks can be reduced.

For instance, AR-enabled smart glasses can supplement conventional paper lists and manuals for standard operating procedures while offering meticulous, visual step-by-step directives to ensure error-free assembly lines. Simultaneously, integrated cameras and sensors play a pivotal role in upholding safety and quality benchmarks, reinforcing workers adherence to stringent standards.

Additionally, during machine malfunctions, smart glasses with the right industrial AR solutions enable remote experts to deliver real-time assistance and facilitate resolution. This reduces requirements for on-site service visits and curbs production downtime. Which not only minimises productivity losses but also assists in remotely training new recruits, helping to alleviate prevalent skills challenges.

Addressing the manufacturing skills shortage

The UK manufacturing industry is currently facing a skills shortage. As a result, the sector regularly accepts untrained workers. Upskilling these individuals, so they can work safely and productively, is extremely important. Incorporating AR technology into this process, as a replacement or supplement for theoretical classroom sessions, facilitates immersive, interactive training, with lifelike 3D models of machinery or equipment mirroring real work environments.

This is enhanced with interactive content such as videos, animations, or technical drawings. This hands-on method speeds-up learning by deeply embedding vital skills into workers’ consciousnesses, improving productivity for new workers and reducing the risks of operational errors.

It also eases the burden on often overextended and resource poor training departments or supervisors created by classic training methods.

What’s more, AR training, doesn’t just benefit brand new members of staff. Carefully curated visual guidance means existing workers can be coached through new tasks for them, such as repairing critical equipment.

Enhancing safety through AR

Safety concerns remain a focus within the manufacturing sector, despite significant advancements that have been made to minimise risks of injury. Now, AR is emerging as a pivotal tool in improving worker safety by ensuring compliance with safety measures and protocols.

Traditionally, frontline workers were heavily reliant on bulky handheld devices, or even fixed computers located at a distance from the production areas, to feed them information about the work at hand. However, AR-enabled glasses have revolutionised this.

The first step to achieve higher levels of workplace safety rolls back to training. Simply put: well-trained staff make less mistakes. Less mistakes on the shopfloor not only boosts output quality, but also improves safety. With AR technology, the specifics of highly individualised processes and machinery which are prevalent in manufacturing can easily be transformed into engaging trainings in a safe environment.

By practising on a virtual model shown via smart glasses or mobile devices first, worker’s mistakes will not lead to safety critical incidents. Furthermore, the visual and interactive character of AR technology promises faster knowledge transfer and better knowledge retention, leading to higher quality trainings and consequently a knowledgeable workforce.

In production, AR-enabled glasses, that seamlessly show digital insights right in the individual’s field of view, help frontline workers by providing real-time, hands-free information about the jobs they’re doing. This reduces traditional safety concerns associated with having to operate machinery while handling additional items.

On top of this, the glasses serve as proactive safety aids, displaying warnings, and guiding workers through step-by-step instructions, reinforcing adherence to factory protocols. They can also alert workers about risks, such as temporarily restricted zones or specific machine procedures, further mitigating injuries.

Navigating the future of manufacturing

As businesses embrace digital transformation, AR will assume a pivotal role in supporting frontline workers across a plethora of sectors. As we’ve seen, manufacturers are already leveraging AR enabled solutions to train and upskill staff, facilitate maintenance of equipment, and ensure product quality.

As technological solutions and the manufacturing industry continues to progress, industrial AR solutions, running on smart glasses or mobile devices such as tablets and smart phones, will become even more pivotal in ensuring businesses meet goals, enhance efficiencies, and achieve innovation.

As such, embracing this technology now, will secure the industry’s future and solidify it as a crucial sector for the UK’s financial success.

Jan Junker is Executive Vice President, EMEA at TeamViewer

Main image courtesy of iStockPhoto.com

Business Reporter Team

Most Viewed

Winston House, 3rd Floor, Units 306-309, 2-4 Dollis Park, London, N3 1HF

23-29 Hendon Lane, London, N3 1RT

020 8349 4363

© 2025, Lyonsdown Limited. Business Reporter® is a registered trademark of Lyonsdown Ltd. VAT registration number: 830519543